Key features and benefits

Conformal cooling channels – Engineered for optimal thermal performance and lifetime ratio.

Tool steel material – Made from premium, industry-approved tool steel grades produced in the EU.

No leakage – Utilizes a single inlet and outlet, effectively eliminating leakage points and simplifying the cooling circuit.

Improved part quality – Uniform cooling reduces warping, sink marks, and stresses for better accuracy and finish.

Reduced cycle time – Faster heat extraction enables quicker solidification and shorter cycles.

Resin property consistency – Even cooling ensures uniform crystallization or solidification for stable properties.

Less scrap and rework – More consistent parts mean fewer defects and less post-processing.

Enhance your Injection Moulding process

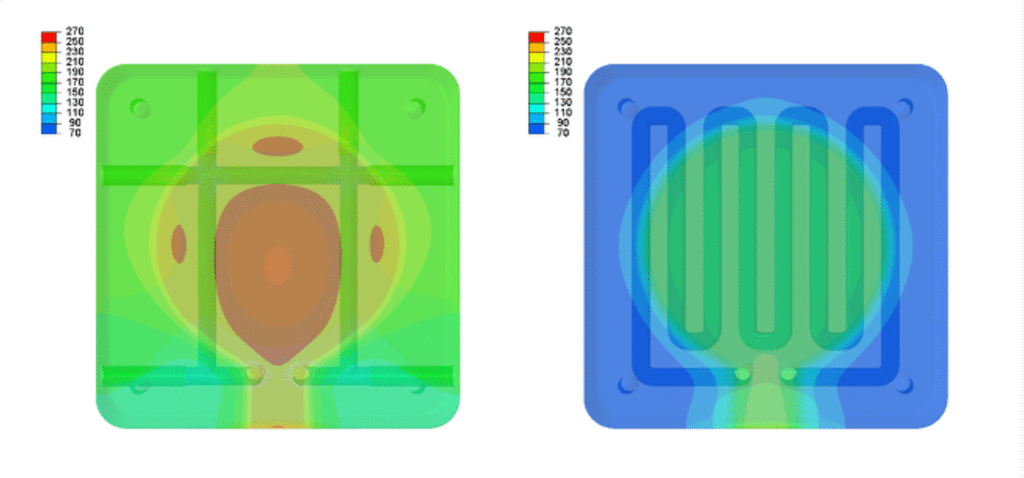

Temperature homogeniety of the working surface

In comparison with the conventionally made mould insert, iTherm mould insert enables more even heat distribution actoss the working surface, resulting in more efficient cooling.

- MFT manufacturing technology ensures smooth (>0,8 Ra) conformal cooling chanels

- More even heat distribution across working surface

Thermal image comparison:

Left: conventional insert with drilled channels

Right: iTherm insert with conformal cooling chanels

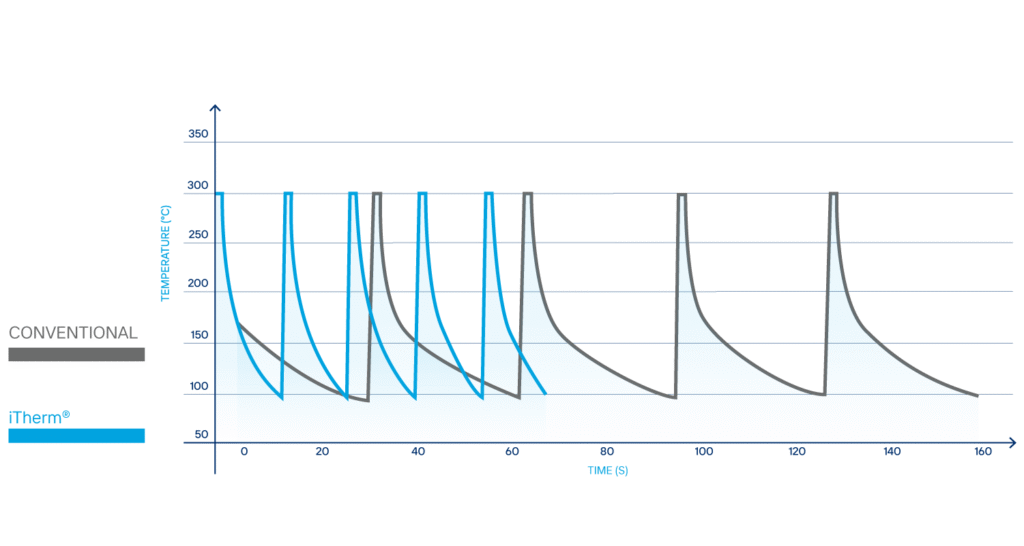

Shorter cycle time

The cooling power of iTherm® Mould insert correlates directly with production cycle time and productivity. Up to 50% cycle time reduction can be achieved by replacing conventional with iTherm® Mould insert.

Predefined Mould Insert models

- Predefined models in HTS standard dimensions and tolerances.

- All models follow HTS design specifications for cooling and service life parameters.

- Lead time: 3-4 weeks.

Flat

DIMENSIONAL RANGE

Dia 55-92

Length 50-120

Cooling power options

10 W/m2

15 W/m2

25 W/m2

Core

DIMENSIONAL RANGE

Dia 1 55-92

Dia 2 48-80

Length 50-120

Cooling power options

10 W/m2

15 W/m2

25 W/m2

Cavity

DIMENSIONAL RANGE

Dia 1 55-92

Dia 2 48-80

Length 50-120

Cooling power options

10 W/m2

15 W/m2

25 W/m2

Rectangular Flat

DIMENSIONAL RANGE

Length 40-260

Width 40-260

Height 50-100

Cooling power options

10 W/m2

15 W/m2

25 W/m2

Rectangular Flat - Extra Stock

DIMENSIONAL RANGE

Length 40-260

Width 40-260

Height 50-120

Cooling power options

10 W/m2

15 W/m2

25 W/m2

Configurable Mould Insert models

- Configurable models in HTS standardized diameters, heights, and tolerances.

- Configurable cavity or core features; dimensions and radiuses.

- All models follow HTS design specifications for cooling and service life parameters.

- Lead time: 5-6 weeks.

Core

DIMENSIONAL RANGE

DIAMETER 55 – 92

LENGHT 50 – 120

Cooling power options

10 W/m2

15 W/m2

25 W/m2

Cavity

DIMENSIONAL RANGE

DIAMETER 55 – 92

LENGHT 50 – 120

SPLIT TYPES

10 W/m2

15 W/m2

25 W/m2

Need a custom engineered solution?

We manufacture custom-designed iTherm® Mould Insert tailored to your injection system and mould geometry.

Customer Success Story

Discover how customers improve part quality, decrease cycle times and improve productivity with iTherm® solutions.