Traditional cooling works great – until it doesn’t.

Straight channels can’t follow the twists and contours of modern moulds and are often unsuitable for detailed and demanding part geometries. When cooling can’t follow the geometry, it leads to uneven heat removal, localised hot spots, longer cycle times – and ultimately, part distortion.

That’s where conformal design changes the game.

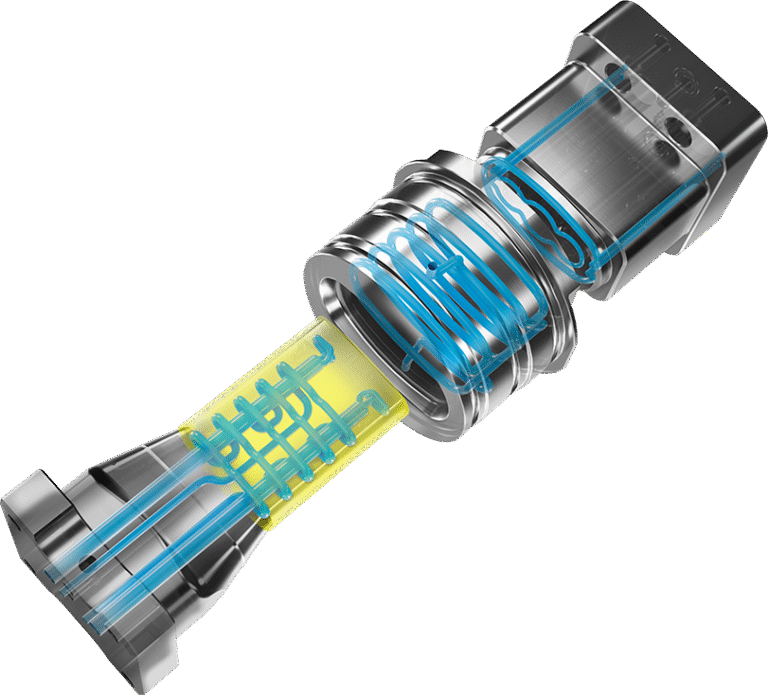

By using additive manufacturing, HTS creates custom-shaped cooling channels that follow the 3D contours of your mould cavity – placing cooling exactly where it’s needed, just below the surface.

Traditional cooling works great — until it doesn’t.

Straight channels can’t follow the twists and contours of modern moulds. That’s where conformal design changes the game.

Standard cooling channels are often unsuitable for detailed and demanding part geometries. When cooling can’t follow the geometry, it leads to uneven heat removal, localised hot spots, longer cycle times — and ultimately, part distortion.

Conformal design solves this. By using additive manufacturing, HTS creates custom-shaped cooling channels that follow the 3D contours of your mould cavity — placing cooling exactly where it’s needed, just below the surface.

Cooling channels are freely designed based on the cooling/heating requirements of the product, without being constrained by the limitations of conventional drilling methods.

Conformally cooled components enable more even heat distribution over the working surface, resulting in more uniform and rapid cooling.

Conformally cooled components usually feature just two cooling water connectors (IN and OUT), ensuring a leak-proof design.

Conformal cooling in injection molding optimizes heat dissipation, allowing faster and more uniform cooling of the mold. This accelerates material solidification, significantly shortening the molding cycle and boosting

production efficiency.

Enhanced cooling control minimizes thermal stresses and reduces defects such as warping and shrinkage. This leads to more consistent part dimensions and superior surface finishes, improving the overall quality and reducing the need for post- production adjustments.

Have a question or need more information? Leave us a message, and we’ll get back to you as soon as possible.