From your first sketch to a fully optimized, production-ready part, we provide full support. Our engineering team combines deep knowledge of materials, thermal dynamics, and advanced manufacturing to design, simulate, test, and produce high-performance components – entirely in-house. That means we control every variable, optimize in real-time, and accelerate innovation at every step.

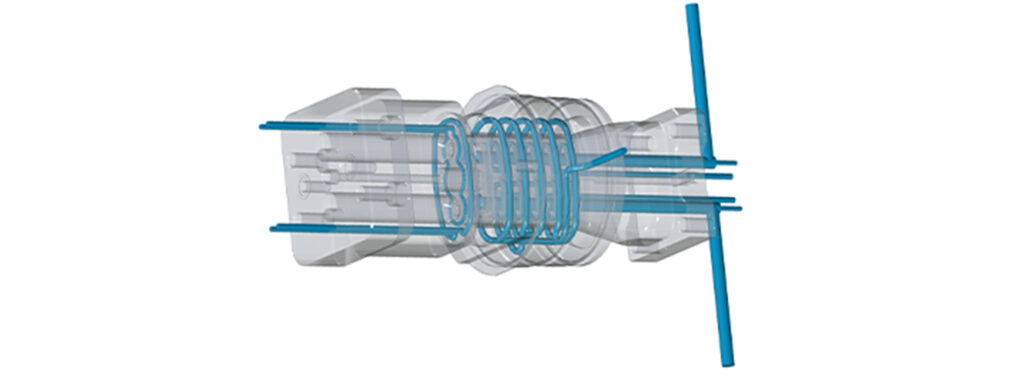

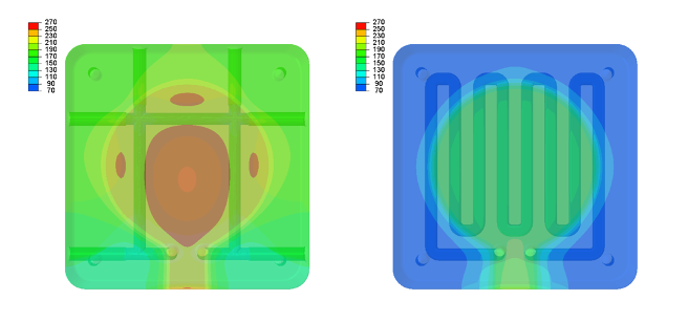

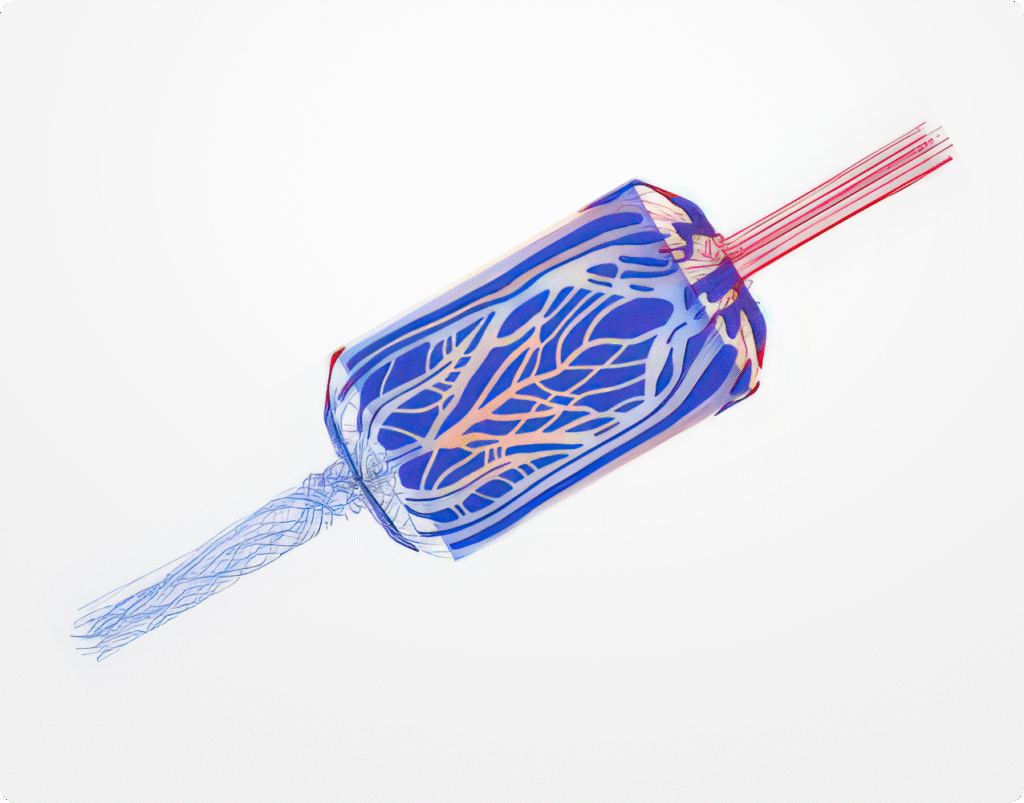

With 15 years of experience in thermal design and conformal cooling, we were among the first to manufacture topology-optimised fluid patterns, pushing the boundaries of thermal management innovation.

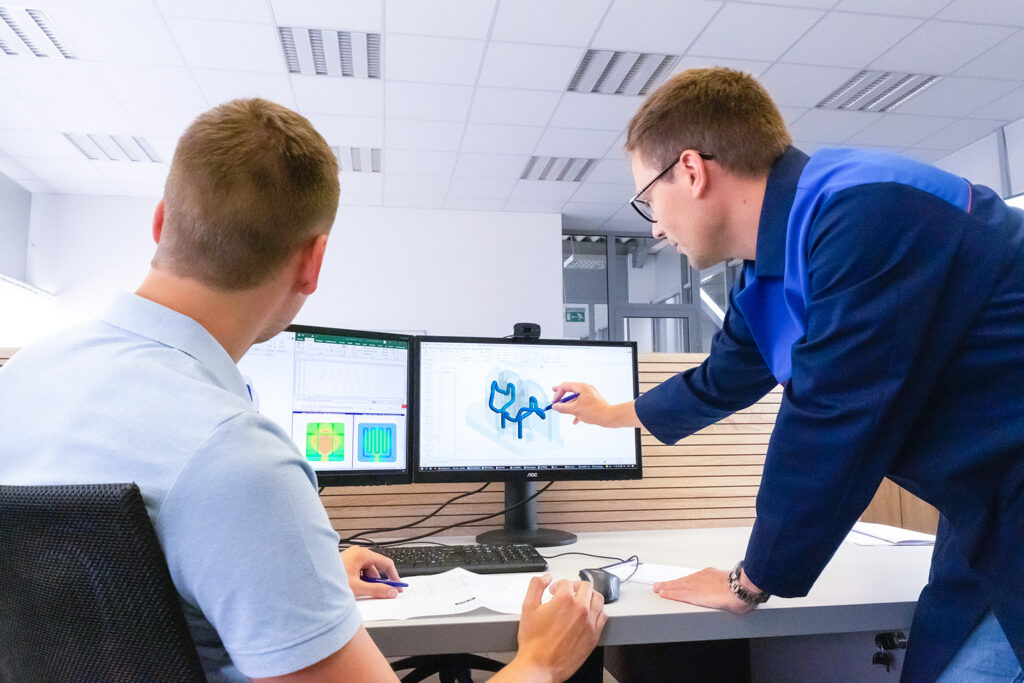

We collaborate with the customer to define the key technical challenges—thermal loads, pressure conditions, flow characteristics—and set the functional and material targets.

From there, we develop initial design concepts and select the optimal solution to move forward.

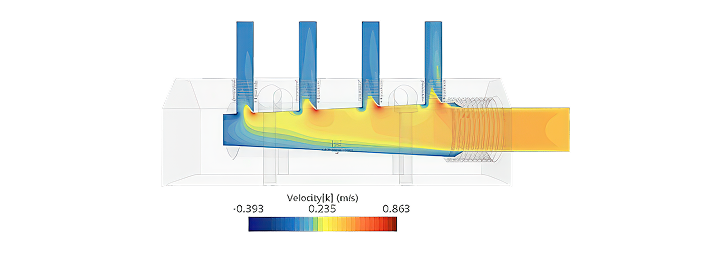

Using tools like Finite Element Analysis (Abaqus), CFD (OpenFOAM), and topology optimization (nTop), we simulate real-world conditions to optimize structure, thermal behavior, and part reliability.

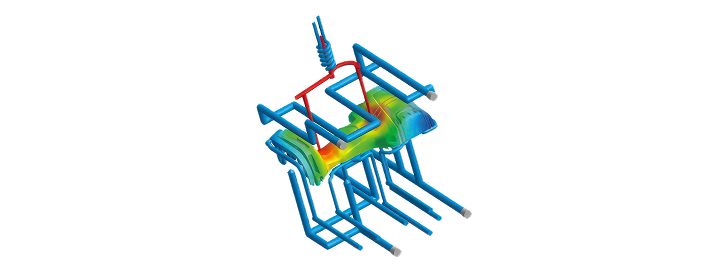

We use generative design, thermal topology optimization, and implicit modeling (including lattices and gyroids) to produce geometries that maximize performance.

What does this mean for you?

Every design is engineered for maximum performance and manufacturability.

Our AI-based generative design process optimizes for both internal flow and heat transfer for maximum thermal efficiency. Using algorithm-driven topology optimization, we engineer material-efficient geometries that are lightweight yet structurally robust.

These designs are ideal for additive manufacturing and maintain full thermal and mechanical functionality while significantly reducing weight and material usage.

Tailored to each application’s specific heat load and constraints, this method produces high-performance, complex geometries that outperform traditional designs and are ready for additive manufacturing.

Our Design for Manufacturing (DFM) process is built around additive:

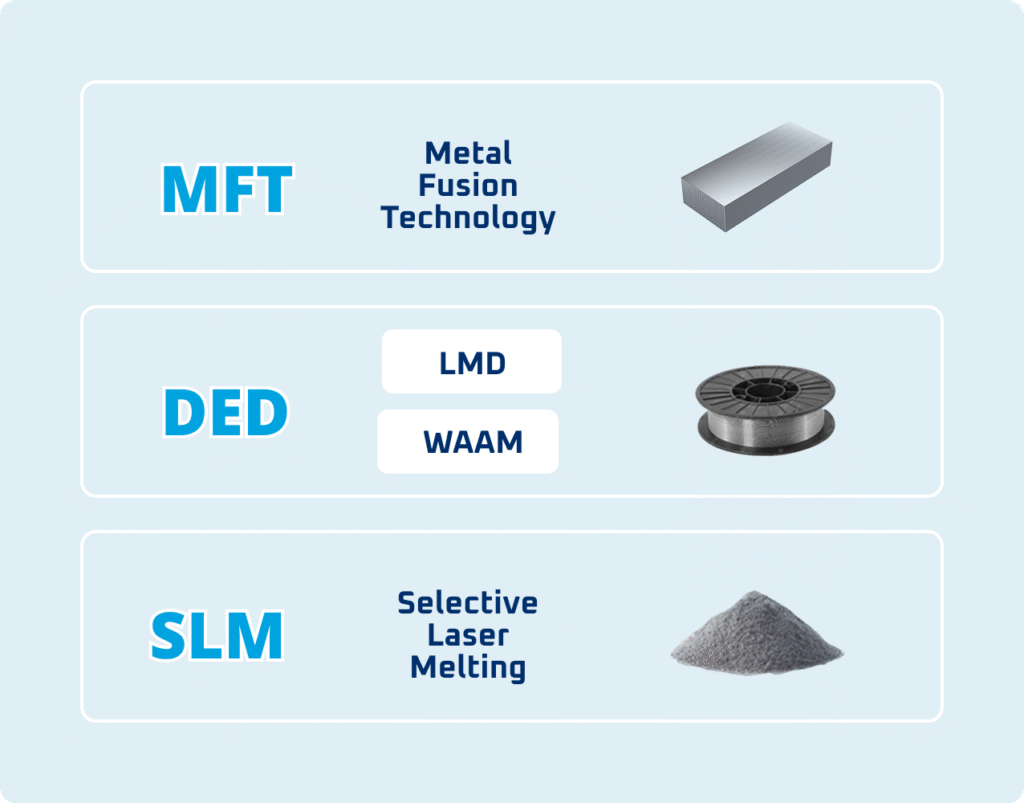

The Full AM Spectrum.

Not every job needs the same tool. That’s why we have four.

We’re the only manufacturer of conformal cooling and flow components using four distinct additive technologies – each applied strategically based on geometry, material, and performance targets.

From fine lattice structures to thick-walled giants, we pick the right AM method for your application.

One conversation could unlock months of production gains.

We use four in-house additive manufacturing technologies – each suited to a different kind of challenge, performance demand, and precision level.

Have a question or need more information? Leave us a message, and we’ll get back to you as soon as possible.