THE CUSTOMER

Caps & closures producer

HTS SOLUTION

iTherm® Mould Insert

THE CHALLENGE

More uniform cooling of the insert surface

OUTCOME

26% lower surface temperature

Case study overview

HTS worked with a closures manufacturer that needed more uniform cavity cooling around critical regions, especially near the nozzle tip and the top surface, to reduce high temperatures and long cycle times.

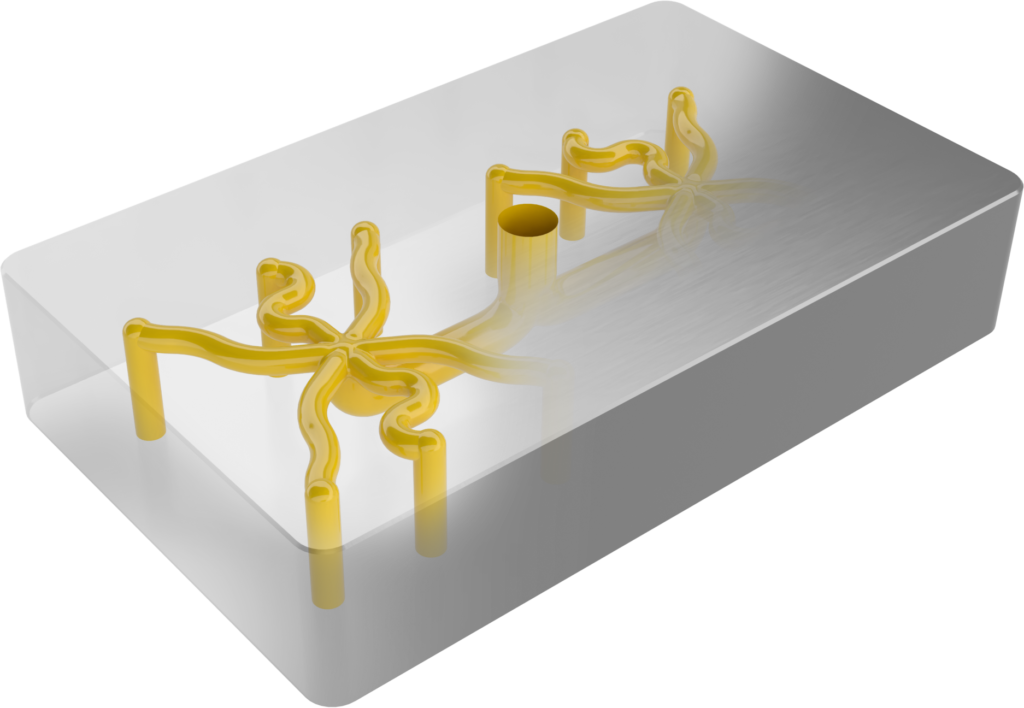

We designed iTherm® conformally cooled inserts with two dedicated cooling loops (one focused on the gate/nozzle tip; another for the top surface), placing cooling channels much closer to the heat-dense areas.

Geometry comparison

Temperature comparison

The temperature distribution of the iTherm® cores is much more even due to improved distribution channels. Max temperatures are also reduced.

Temperature comparison

Temperature distribution of the iTherm® cores is much more even due to improved distribution channels. Max temperatures are also reduced.

Flow analysis

Parallel distribution channel design causes lower rise in temperature of the coolant.

Pressure drop & flow rate comparison

Due to lower resistance of the parallel flow, the pump can achieve much greater flow at the same pressure drop and achieve a greater cooling effect.

Parallel flow channels

Due to lower resistance of the parallel flow, the pump can achieve much greater flow at the same pressure drop and achieve a greater cooling effect. Rabimo nove slike

See other case studies

Discover how customers improve part quality, decrease cycle times and improve productivity with iTherm® solutions.