THE CUSTOMER

Preform manufacturer

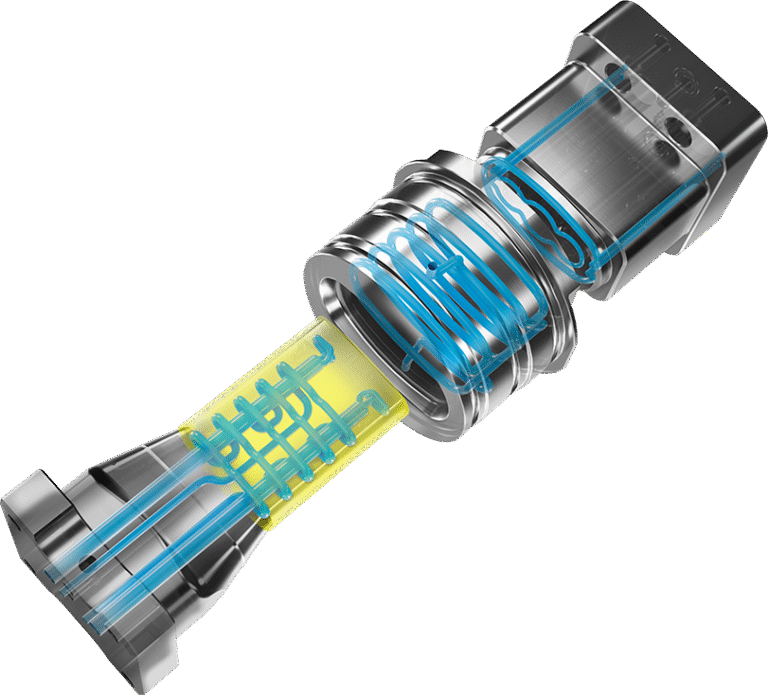

HTS SOLUTION

iTherm manifold with continuous transitions and fewer splits for controlled, symmetric flow.

THE CHALLENGE

Balanced filling, faster material change and lower pressure drop.

OUTCOME

50% improvement in filling balance

Case study overview

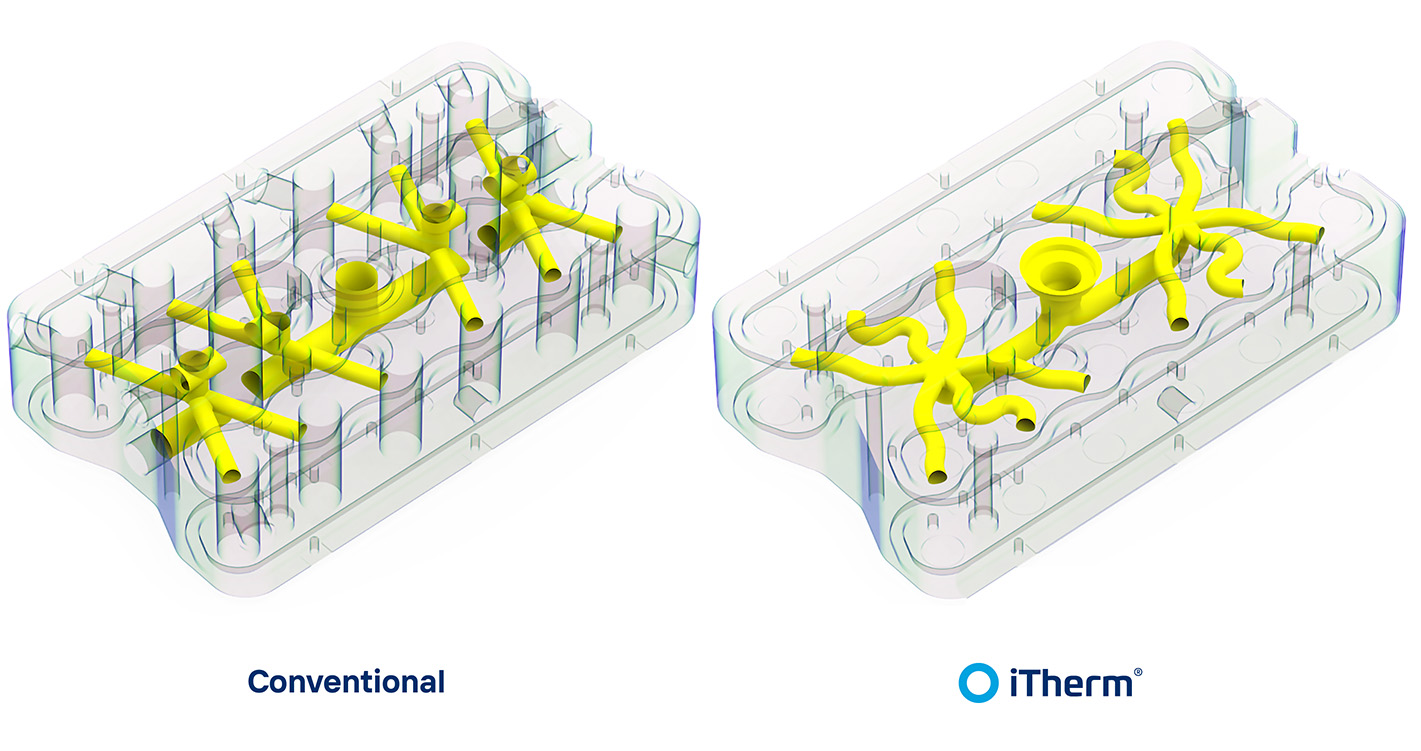

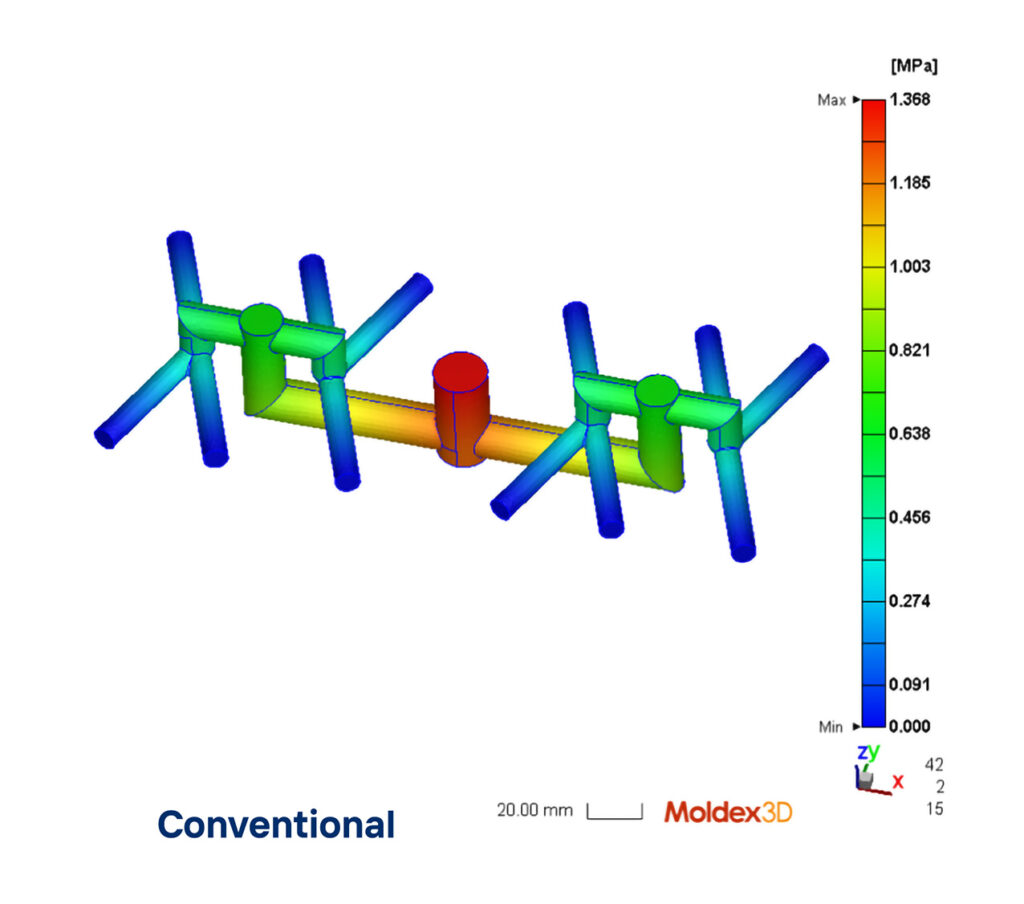

THE CHALLENGE: Conventional drilled-channel design caused non-uniform filling. Multiple 90° splits (2 → 2 → 3) created too many subdivisions, broke symmetry, and limited flow control.

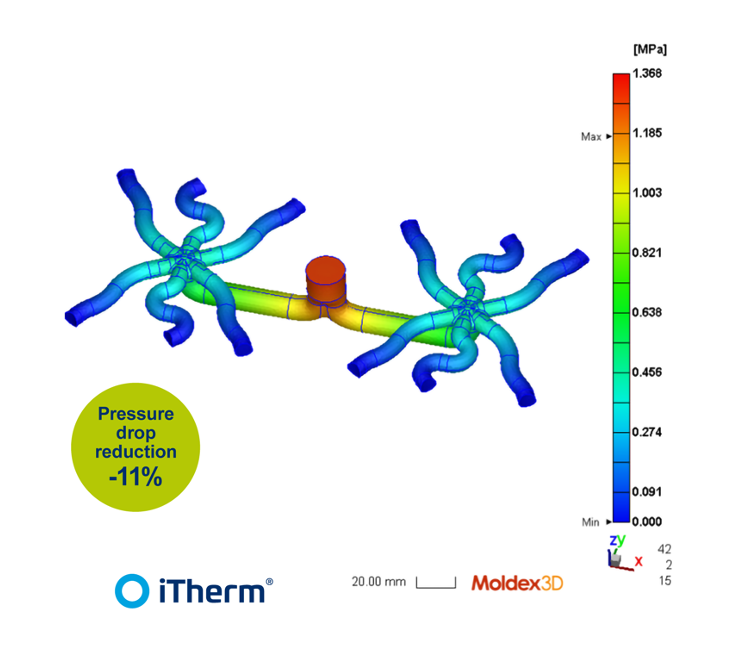

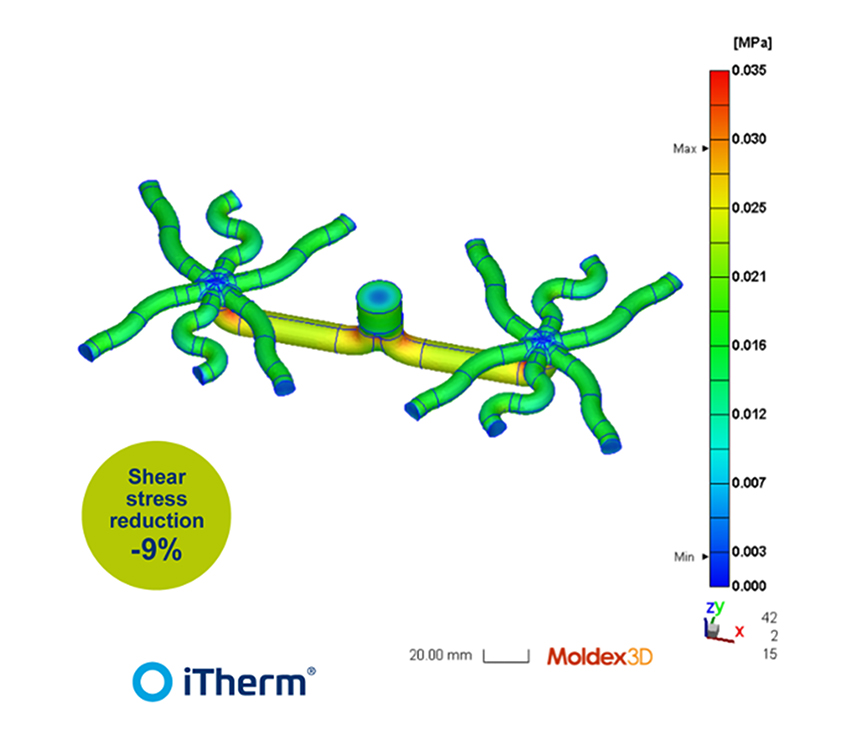

HTS SOLUTION: HTS introduced continuous transitions, eliminating 90° angles. Flow was split directly 2 → 6, reducing subdivisions and ensuring controlled, symmetric distribution.

HTS and the customer iterated multiple designs, all supported by simulation and direct comparison of results. Step by step, the geometry was refined until the final optimized design was achieved, as shown in the figures, delivering measurable improvements in uniformity, efficiency, and reliability.

Outcome

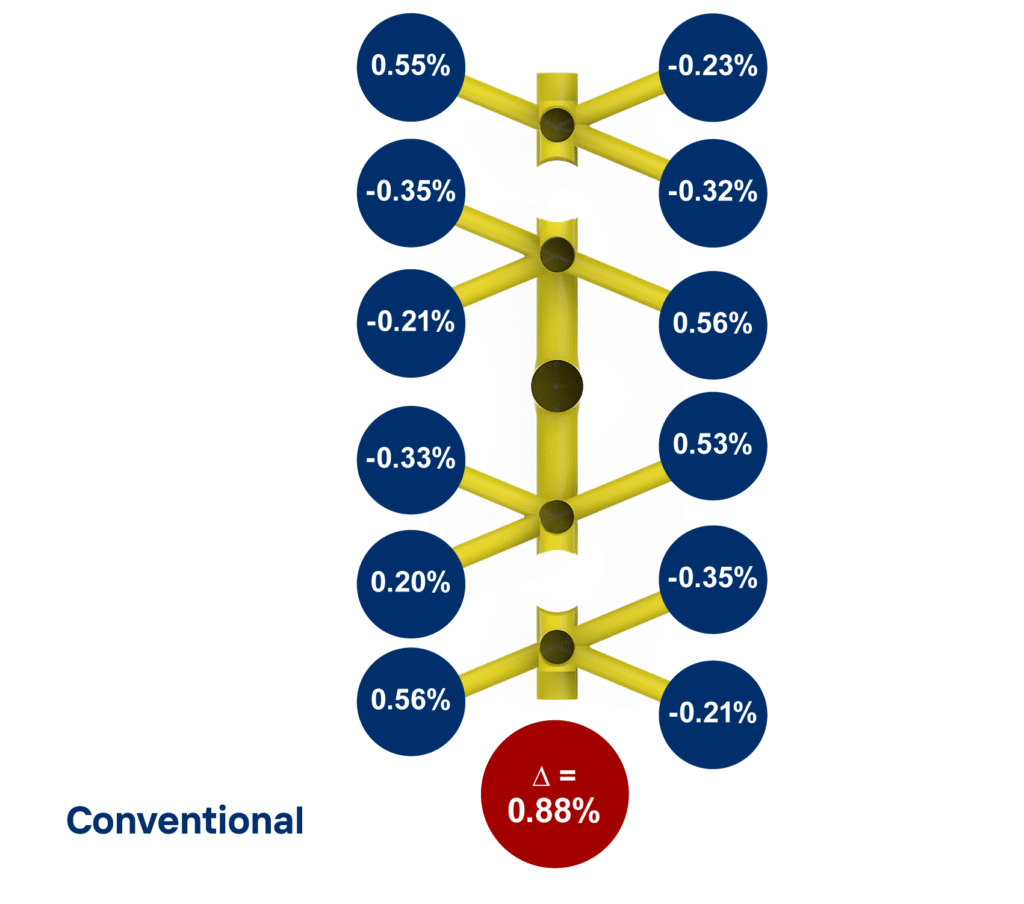

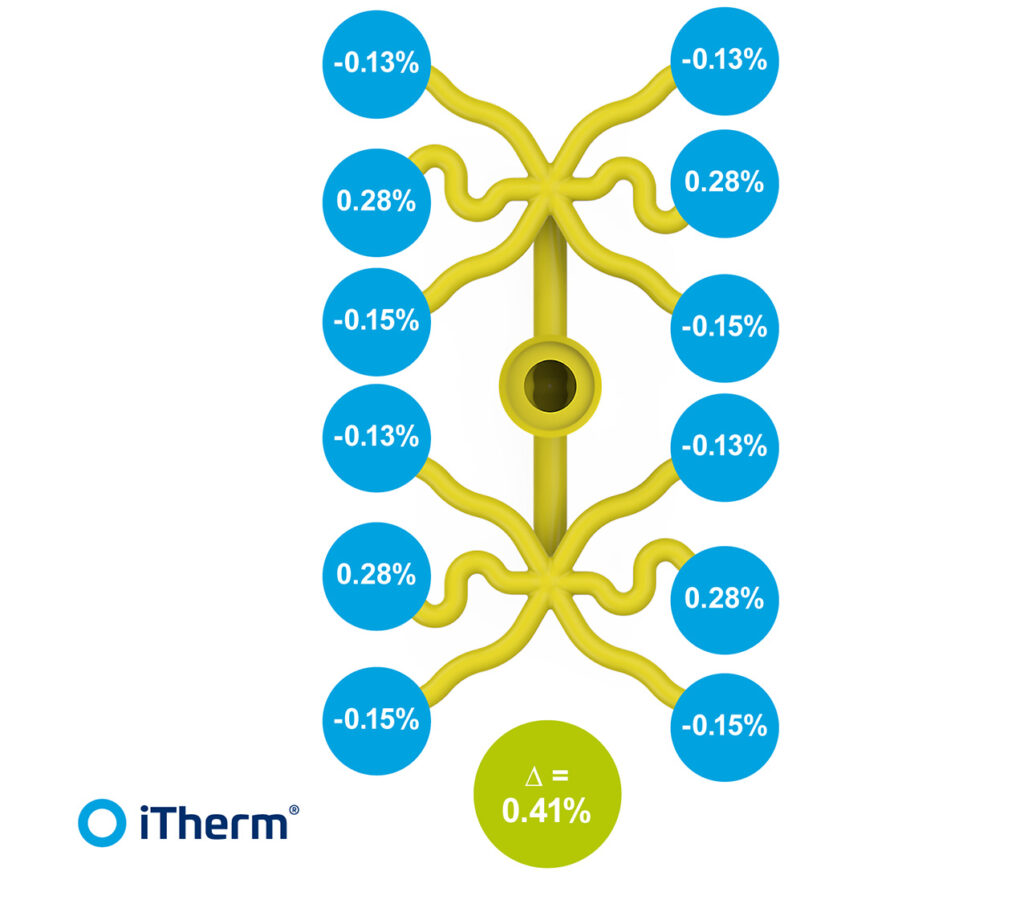

- Filling imbalance cut from 0.88% → 0.41% (>50% improvement).

- Pressure drop reduced by 11%, improving flow efficiency in the hot-runner manifold.

- Shear stress reduced by 9%, lowering material degradation and extending manifold life.

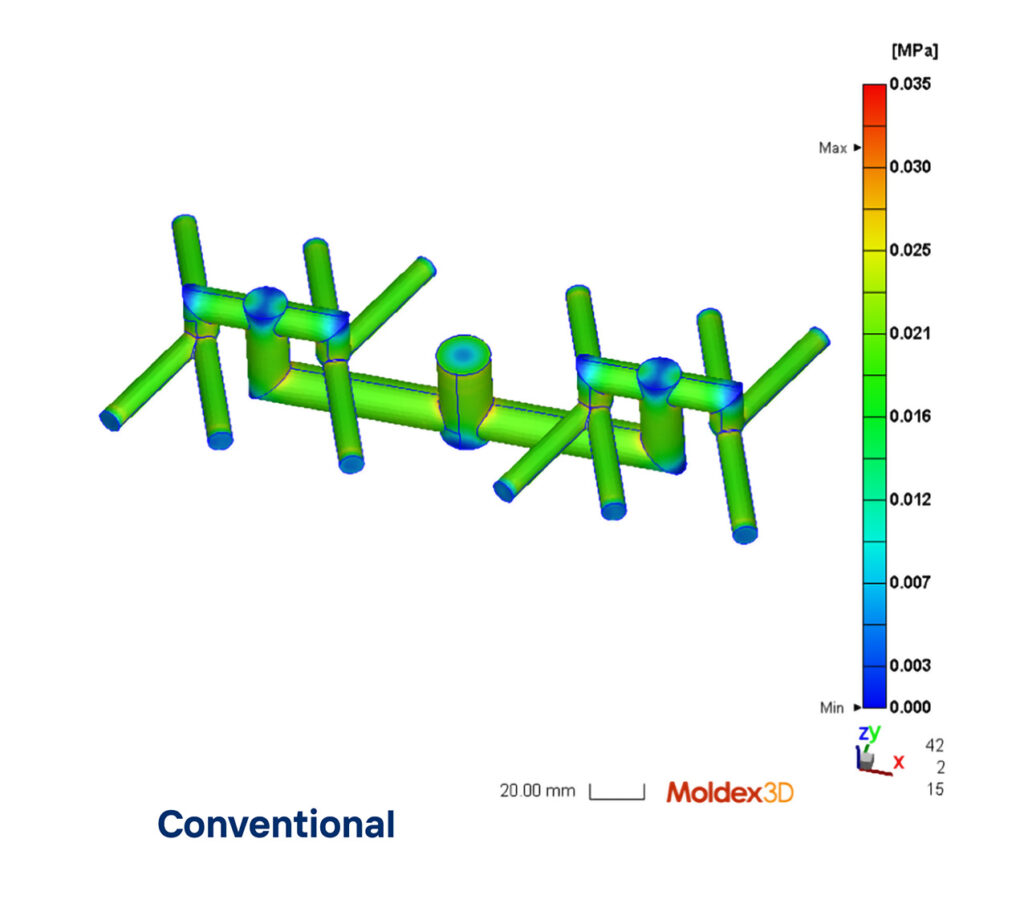

Geometry comparison

Conventional drilled-channel design caused non-uniform filling. Multiple 90° splits (2 → 2 → 3) created too many subdivisions, broke symmetry, and limited flow control.

HTS conformal design introduced continuous transitions, eliminating 90° angles. Flow was split directly 2 → 6, reducing subdivisions and ensuring controlled, symmetric distribution.

Complete filling uniformity for non symmetrical cavitation

Flow analysis

Improved filling balance

Differences in volumetric resin flow are lower compared to conventional manifold. This ensures better filling balance and part quality.

Pressure drop reduction -11%

iTherm® channel design also lowers the flow resistance, reducing the strain on the injection molding machine and tooling.

Shear stress reduction - 9%

Shear stress is reduced, leading to improved resin quality.

See other case studies

Discover how customers improve part quality, decrease cycle times and improve productivity with iTherm® solutions.

See other case studies

Discover how customers improve part quality, decrease cycle times and improve productivity with iTherm® solutions.